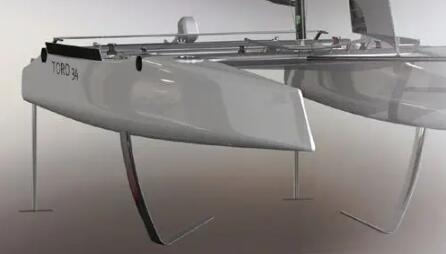

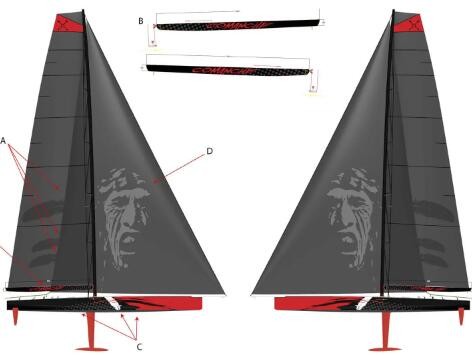

產(chǎn)品簡介由 VPLP/Verdier 設計,,并在短短 12 個月內(nèi)在美國最大的海洋烤箱中建造,,超級游艇 Comanche 旨在成為有史以來最快的單鷗。 她采用預浸料碳纖維制成,,產(chǎn)生了一個非常輕巧和堅固的船體,,并具有一個罐頭龍骨、水板,、鎮(zhèn)流器和大帆面積,。 Comanche 具有寬、淺的船體和高功率重量比,。 Comanche 的成就包括: 打破了近 5 小時的紐波特百慕大賽記錄,。新的跨大西洋單鷗西東紀錄 5 天,,14 小時,21 分鐘,,25 秒(超過 24 小時,,比以前的記錄快) 先進的建設能力 對于超級游艇科曼奇的建設,店鋪的物理空間被徹底改變,。 用于烹飪船體和甲板復合部件的模塊化烤箱現(xiàn)在完全填充了設施內(nèi)部,,小型烤箱可以處理大樓內(nèi)部的艙壁和小型零件。 烤箱 目前三個烤箱中最大的是 110 英尺 x 36 英尺 x 20 英尺(33.5m x 11.1m x 6 米),。 屋頂是可拆卸的,,墻壁和屋頂是模塊化的。 多個加熱器的總?cè)萘砍^ 150 萬 BTU,, 建筑擴建了 大樓,,現(xiàn)在有一個 “潔凈室”,用于切割織物,。 冷藏預浸料材料的儲存位于附近,。 英文介紹Designed by VPLP/Verdier and constructed in the largest marine oven in the United States in just 12 months, Superyacht Comanche is intended to be the fastest monohull ever built. She is constructed of pre-preg carbon fiber, resulting in an extremely light and strong hull and features a canting keel, daggerboards, water ballast and large sail area. Comanche features a wide, shallow hull and high power-to-weight ratio. Comanche’s accomplishments include the following: Setting the 24-hour monohull speed record of 618.01 miles (traveling at an average speed of 25.75 kts) Line honors at the 2015 Rolex Sydney Hobart Yacht Race Breaking the Newport Bermuda Race record by almost 5 hours Setting the new Transatlantic monohull West East record of 5 days, 14 hours, 21 minutes, 25 seconds (over 24 hours faster than the previous record) Advanced Construction Capabilities For Superyacht Comanche’s build, the shop’s physical space was completely transformed. A modular oven for cooking the hull and deck composite parts now completely fill the interior of the facility with smaller ovens handling bulkheads and small parts elsewhere in the building. The Ovens The largest of the three ovens is currently 110’ x 36.5’ x 20’ (33.5m x 11.1m x 6m). The roof is removable and the walls and roof are modular. Multiple heaters have a combined capacity of over 1.5 million BTU’s. Building Extension The building was extended and now hosts a “clean room” for cutting fabric. Storage of refrigerated prepreg materials is located nearby. |

| 39英尺傳統(tǒng)型2艙木質(zhì)帆船(補助帆桁) |

2023-09-28

|

查看詳情 >> |

| 98英尺傳統(tǒng)型尾部開放式巡游帆船游艇(一鍵式航行控制帆船) |

2023-11-14

|

查看詳情 >> |

| 37米傳統(tǒng)型尾部開放式超級帆船游艇(三桅式補助帆桁游艇帆船) |

2023-11-22

|

查看詳情 >> |

| 傳統(tǒng)型3艙炭纖補助帆桁巡航競賽帆船(經(jīng)典日間游艇帆船) |

2023-12-06

|

查看詳情 >> |

| 60米傳統(tǒng)型快速巡游超級帆船游艇(鋁制甲板會客區(qū)競賽帆船) |

2024-01-05

|

查看詳情 >> |